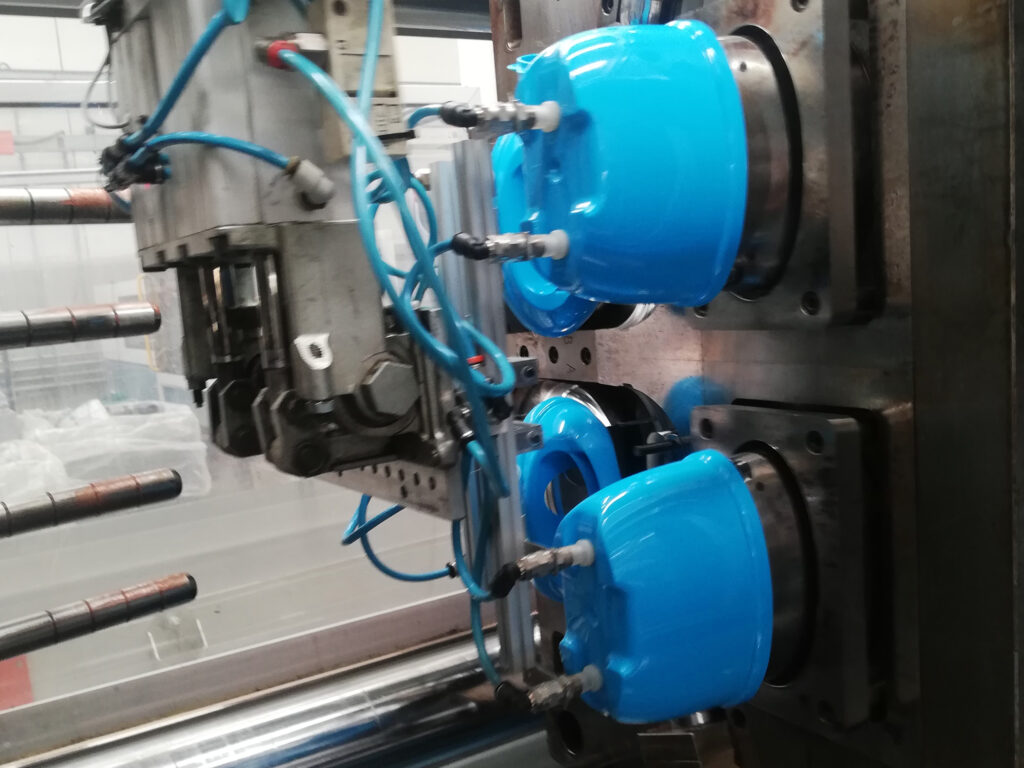

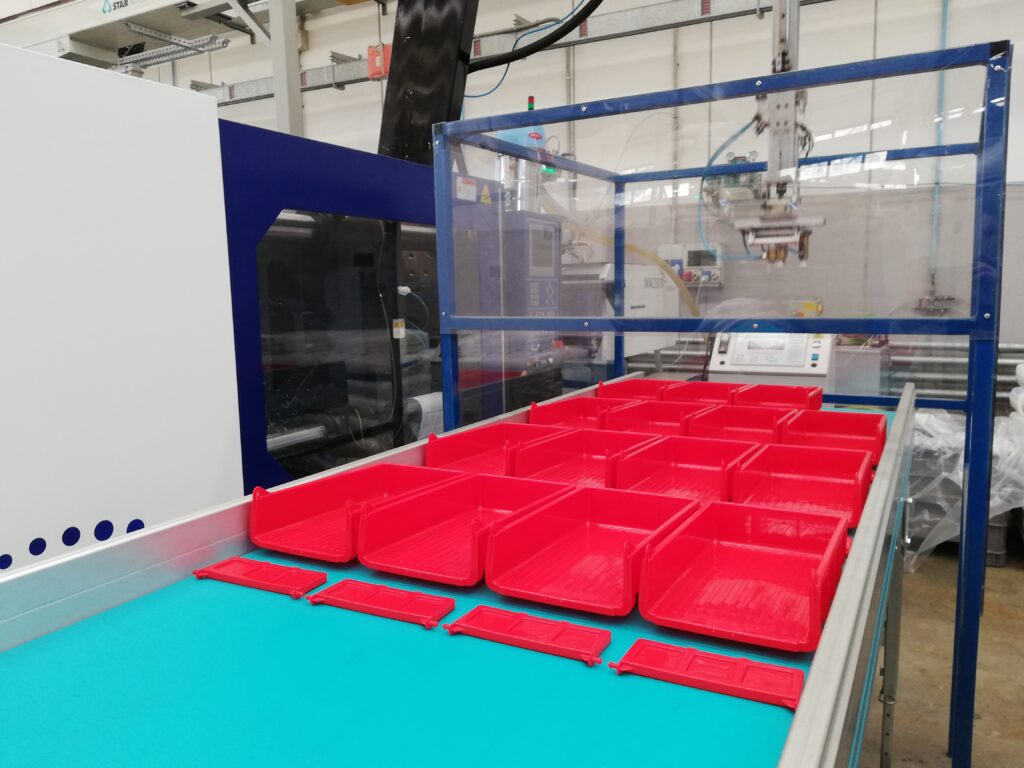

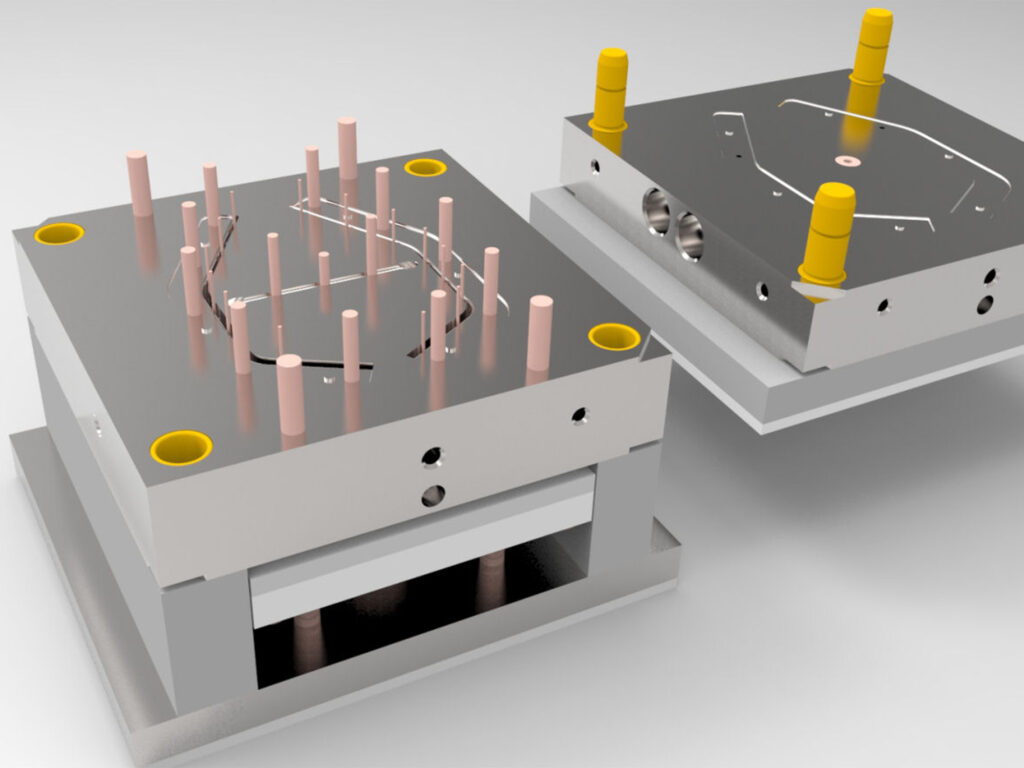

Our fleet of machines includes technological injection moulding presses from 65 to 300 tons, able to mould from a few grams to 850 gr. Our technologically advanced presses are equipped with manipulators for picking up pieces, which increase efficiency and productivity. They are also composed of dehumidifiers (for the most technical materials) and temperature control units to thermoregulate the temperature of the mould.

All the machines are organised and prepared to produce 24 hours a day without interruption.